ABOUT USABOUT USZepress Tech Ltd. is a modern and innovative manufacturer of press products in different kinds of material. Press products cover the material: |

SCIENTIFIC MANAGEMENT ADVANCED PRODUCTION TECHNOLOGY Adhering to the concept of integrity, enterprising, pragmatism and efficiency, We hope to take innovation and technology as its core competitiveness to become a standard-setter in the field of global fluid transportation, making fluid transportation safer, more environmentally friendly, and more efficient; becoming a leader in the fluid transportation industry. |

IPS Press fitting (Carbon steel)

IPS Press fitting for Gas (Carbon steel)

IPS Press fitting (Stainless steel)

Stainless steel press fitting (304)

Stainless steel press fitting (316L)

Carbon steel press fitting with EP coated

Ball Valve (Brass + Bronze)

Carbon steel press fitting

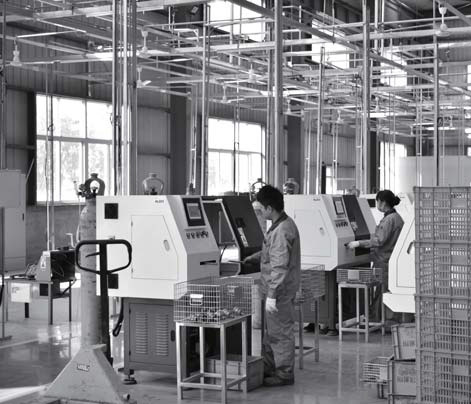

PRODUCTION ABILITY In order to increase the capacity and keep stabilization dimensions of fitting, the most of process are made by full automation equipment (from cutting the raw material to forming into final shape include the welding and PE costing prcoess). The equipment is designed to be modularity, could be builtup to fit the different shape products as well as different sizes. The equipment was invented and patterned in United Status. |

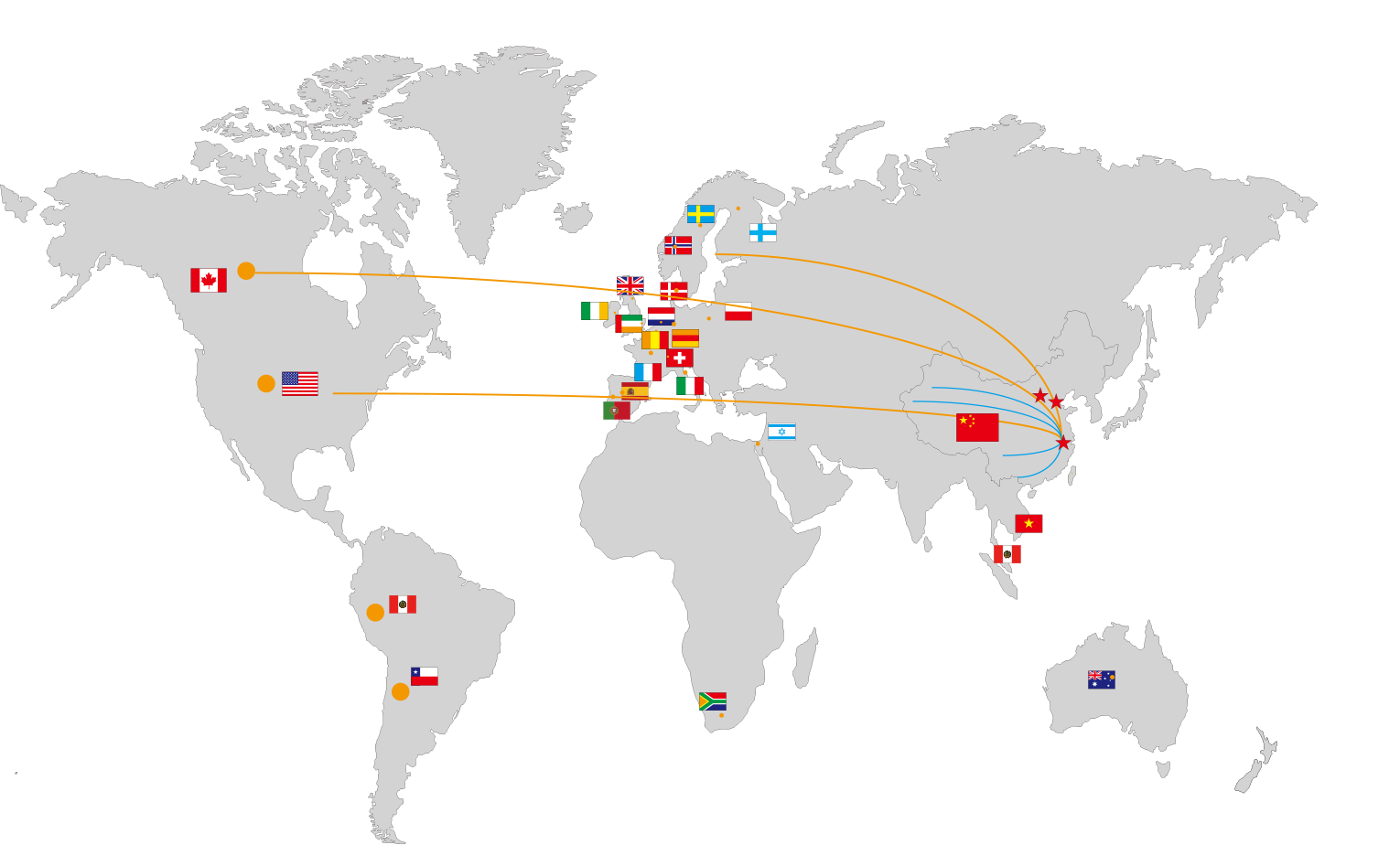

Conform to the standard over the world Since its establishment, the Quality Inspection Center has always adhered to honesty and excellence. It has successively passed ISO9001, ISO14001,ISO45001 and other series of certifications, forming a professional inspectionservice platform integrating product inspection, method development, and consulting services. |

NEWS

NEWS

| Leave A Message If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.  *

*

Send Message

|

Service Tel: +8613917344584

Service Tel: +8613917344584  Email:Sales@zep-tech.net

Email:Sales@zep-tech.net